COMMERCIAL

MARINE

features and benefits

Fuel Right products have been used extensively in the commercial marine sector for more than a decade. With recent changes to IMO Annex VI and the move to lower sulfur marine fuels, Fuel Right technology is more relevant today than it has ever been.

Dissolve and prevent sludge formation

Cleans tanks, fuel strainers, purifiers, fuel lines and filters

Protect system from corrosion related to the presence of microbes (MIC)

Improve lubricating oil life expectancy

Optimize fuel economy and improve fuel lubricity

Suitable for use in all types of fuels (ULSD, MDO, MGO, VLSFO, HFO)

Dissolve and prevent sludge formation

Cleans tanks, fuel strainers, purifiers, fuel lines and filters

Protect system from corrosion related to the presence of microbes (MIC)

Improve lubricating oil life expectancy

Optimize fuel economy and improve fuel lubricity

Suitable for use in all types of fuels (ULSD, MDO, MGO, VLSFO, HFO)

RESULTS

These images are from the interior of a super yacht operating in the South East Asia region. Prior to implementing a Fuel Right program, the tanks were contaminated with sludge as shown in the picture above. A Fuel Right program was adopted and the tanks were inspected one year later. The clean tanks are what was found after one year of a continuous Fuel Right program. The results speak for themselves.

reduced emissions

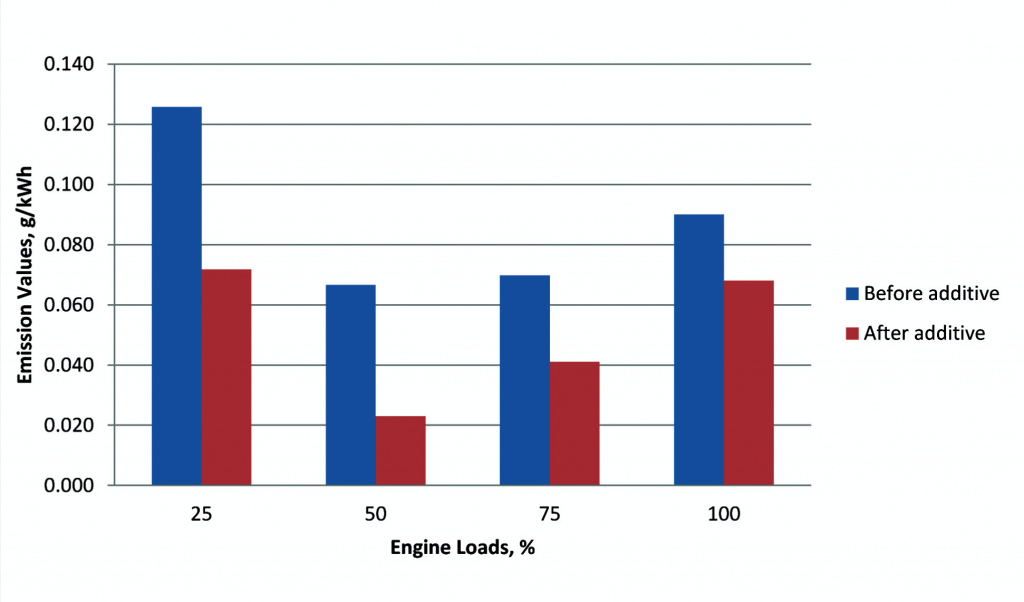

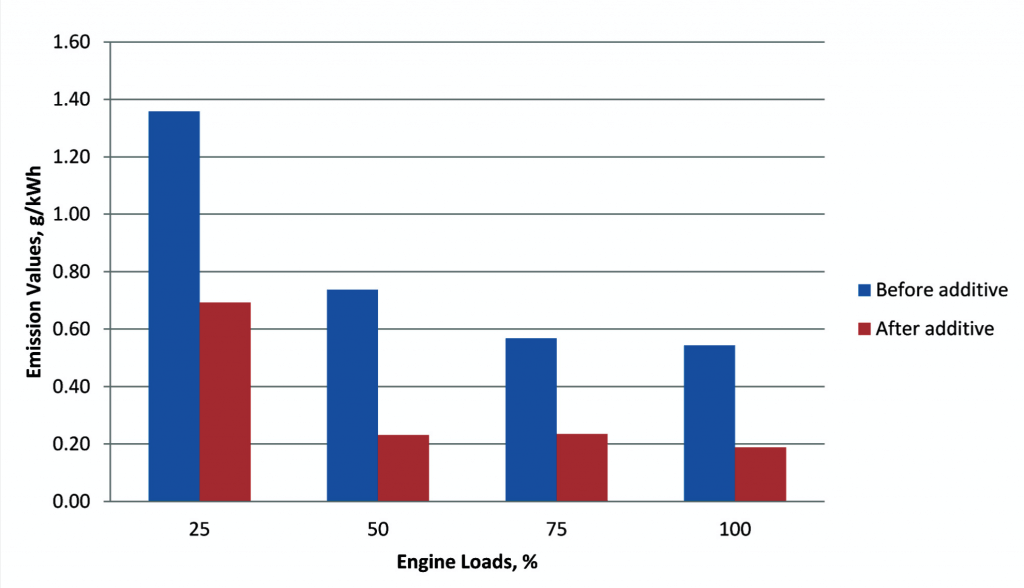

Tightening environmental emission regulation is affecting the marine sector. Fuel Right plays a significant role in reducing emissions. Improved combustion equates to reduced fuel consumption and reduced carbon build up in the engine’s cylinders. Studies carried out on ferry with a four stroke medium speed diesel running on ultra low sulfur diesel fuel demonstrated a significant reduction in emissions. Testing was conducted in accordance with MARPOL Annex VI NOx technical code. Testing results showed a reduction in NOx, SOx, CO, HC and PM.

Fuel Right reduced particulate emissions by 38%

Fuel Right reduced HC emissions by 60%

*Testing performed independently by Istanbul Technical University – Department of Naval Architecture and Ocean Engineerin

It is important to note that the fleet of vessels within this ferry company previously suffered from serious fuel contamination issues and high filter demand despite the use of a competitive additive that claimed to remediate these issues. Since adopting Fuel Right into their fuel delivery, fuel efficiency has improved substantially and filter replacement cycle now meets the OEM engine manufacturer’s recommended replacement interval. Emissions are obviously lower as well.

OUR EXPERIENCE

We have been providing our technology to fleets of marine vessels worldwide.

Offshore Platforms

Offshore Service Vessels

Workboats

Fuel Barges

Ferries

Chemical Tankers

Freighters

Container Vessels

Offshore Platforms

Offshore Service Vessels

Workboats

Fuel Barges

Ferries

Chemical Tankers

Freighters

Container Vessels

what our clients say

Jean-Marc Reich - Senior Marine Engineer, Atlantic Towing

"I was the person who started this program in the tug fleet as well as onboard the Atlantic Tern. We have had good results using this product to help keep our tanks, engine fuel lines, filter housings and injection system clean. As a side effect we have less carbon build up in the L/O spin filter onboard the Atlantic Tern which will help extend L/O life expectancy. The Tern is a good example as this vessel is used for stbd duties and operates for long periods of time at low power and speed. For an older engines equipped with mechanical injection and fixed timing this is a poor operating profile. The Fuel Right additive is used to assist with clean burn."

Konstantinos Pegios - Technical Dept. Manager, Elin Shipping Company

"Our fleet consists of three vessels. Two tanker/ro-ro vessels that operate solely on MGO and one chemical tanker that operates primarily on IFO 180 but uses MGO to enter/leave ports. We frequently had a lot of problems with bacterial infections in MGO storage tanks. At the time, we were using Bioguard to treat the MGO tanks and while it was somewhat effective, we actually had to manually clean the MGO tanks every 2,5 years (when the vessels were dry-docked) in order to remove sludge. In May 2015 we started using Fuel Right additive to all our bunker tanks both in MGO and IFO. Immediately we noticed a night and day difference in MGO tanks. There were no problems with microbial infection whatsoever. In fact, we have now stopped using the onboard microbial test kits and we can almost strip the tank to its bottom without having problems with filters clogging as we had before using Fuel Right. I personally inspected the MGO bunker tanks of one of our vessels that was dry-docked on September 2015. The tanks were clean. As for the IFO 180, I carried out a lot of tests, with and without Fuel Right during these eighteen months over several bunkerings as to ensure that I could attribute any positive results to Fuel Right and not to the possible variations in bunker quality. I can now attest that there is less sludge production and the fuel filters’ cleaning intervals increase significantly, about 30% when using Fuel Right. Bunker quality of course still remains of great importance. Overall, ours has been a positive experience. We intend to keep using Fuel Right in the future, treating our MGO and IFO bunkers on a continuous basis."

China Energy Shen Hua

China Shen Hua is a world leading coal based integrated energy company. It operates mainly for the development and operation of one of the largest coal fields in China – China Shenfu Dongsheng Coal Field. ShenHua first trialed Fuel Right in 2016 and has since adopted the use of Fuel Right across the fleet of 40 ships ranging from 49,000 tons thru 76,000 ton displacement. ShenHua has experienced a significant improvement in operation efficiency. They have reported in excess of 6% improvement in fuel economy, significant reduction in purifier and filter maintenance and reported significant reduction in Sox, NOx and CO2 emissions.